Spraying various coatings on the surface of the product is one of the most important surface treatment processes, which can not only make the product look good, but also protect the product substrate. Plastic spraying and spray painting are two widely used spraying processes. Although they both belong to spraying, there are certain differences.

To say what is the difference between them, I believe many people have not figured it out, and some people may even think that this is a different name for the same process, but in fact, plastic spraying and spray painting are two different processes, and the equipment used is the same as The process flow is also different.

Spray Paint

Spray painting is a simple and commonly used surface treatment process. After pouring paint into a container and pressurizing it with mechanical equipment, the paint is sprayed on the product in the form of mist to form a layer of paint film. Semi-finished products play the role of anti-rust, anti-corrosion and decoration. The painting process is widely used in ships, locomotives, bridges, machinery and other fields.

According to the mode of operation, painting can be divided into manual painting and automatic painting.

Hand-painting is a hand-held spray gun that sprays the product according to the shape of the workpiece. The advantages of the spray gun are flexible operation, suitable for different environments, products of different shapes and sizes, simple equipment, and low energy consumption. However, the production efficiency of the handheld spray gun is low, and the spray quality is also unstable.

Automatic painting is the use of mechanically manipulated spray guns to spray products. The productivity is higher and the spraying quality is stable, but most of the equipment is not cheap and the structure is more complicated.

Spraying can also be divided into two types: air spraying and high pressure airless spraying. Air spray painting uses a spray gun as a tool, and the paint is blown away, atomized, and sprayed on the surface of the product by the airflow of compressed air to form a paint film. High-pressure airless painting uses a high-pressure pump in a closed container to pressurize the paint and spray it out from the spray gun. Due to the sudden drop in pressure, it expands violently and atomizes, and sprays on the surface of the workpiece to form a paint film.

Plastic Spray

Plastic spraying is a widely used metal surface treatment technology, which is very popular in the fields of hardware, home decoration and building materials. Compared with painting, plastic spraying is more complicated. It is a process of spraying paint powder directly on products through equipment, also known as electrostatic powder spraying.

Plastic spraying can directly use paint powder, which does not need to be diluted with liquid, and has less harm to the environment and human body. The coating quality after this kind of electrostatic spraying is very good, and the adhesion is also strong; the technical requirements for workers are also relatively low, the curing time is short, and there are many advantages such as no liquid sagging.

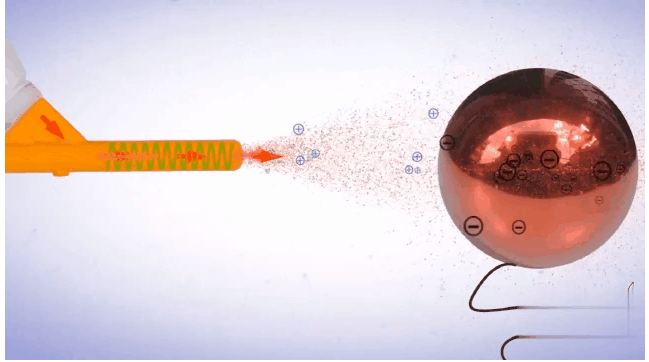

During the plastic spraying process, the powder coating contained in the container is sent to the nozzle of the spray gun by means of compressed air, and high-voltage static electricity will be generated at the front of the nozzle of the spray gun, and an electrostatic field will be formed.

When the paint powder passes through this electrostatic field, it will discharge them, and finally each powder will become a charged paint ion. Under the action of electrostatic force, when it is sprayed, it will be charged by the opposite polarity Attract and thus adsorb on the surface of the product.

When the paint powder accumulates more and more, the charge will also accumulate more. When it reaches a certain thickness, the charged powder will be repelled by the charged powder covering the product, and the paint powder will no longer continue to accumulate.

Introduction to Be-cu:

Be-cu one-stop cloud manufacturing platform for mechanical parts, selected as a national service-oriented manufacturing demonstration platform, has connected 1,000+ high-quality factories, and provides parts rapid proofing and small batch testing for 40,000+ hardware manufacturing customers in 30+ countries and regions around the world Production, large-scale mass production in one of the non-standard parts processing services, covering machining, 3D printing, prototyping, sheet metal processing, injection molding. Click “Quote Now” to upload the drawing with one click, and get the quotation in 5 seconds.

0 Comments